My amazing wife bought me a 3D printer for Christmas this year (along with some other dope stuff!). She bought me the Creality3D Ender 3, which I think is the best ~$200 3D printer on the market. I was eager to see if I got a 3D printer, so I was up at 6:30 am on Christmas morning READY to rip into presents!

Small backstory

I've wanted a 3D printer for a year or so now. I realized the usefulness a 3D printer could bring to my life when my friend Wil started to build a home security system with Pi Zero W's. He was assembling a custom system (both hardware & software) and one of the issues he faced was finding a case for the Pi Zero that integrates the camera nicely. There were also questions about how to handle power (mount a battery? where? hardwire?) and how to actually mount it to the various places they would need to go. Wading through the hundreds of results for Pi cases on Amazon was agonizing. While we discussed the build, we talked about how we can build better software than some of the camera products out there but we can't compete on the enclosures they can create; that's our hard cap on the quality of the system we can make. Then, without even the slightest thought, I joked:

What if we designed the case we want and 3D printed it? Then we could build the complete system we want!

I said that to get a laugh. Kind of like dropping a quip about Bitcoin into conversation. What I didn't realize was this would eventually turn into an obsession! It set me down a path to building my own home IOT solutions. With 3D printing, it's now possible for me to design a custom enclosure for the thing I'm trying to solve along with the custom software needed to get the job done.

Assembling & first print

The Ender 3 was pretty easy to assemble thanks to a bunch of resources on YouTube. I watched this awesome assembly video from Tom a few times before and while putting together my Ender 3. If you're about to assemble an Ender 3, that's the video you need to watch! Lots of great tips for getting set up correctly. Specifically, I want to call out the tips about getting your eccentric nuts perfectly tuned before putting everything together. It's a little hard getting access to a couple of those eccentric nuts once everything is assembled. It's also hard to tune the rollers roll once they're connected to the stepper motors.

After about an hour of the assembly I was finally ready to get my first test print going! The Ender 3 does not have an auto bed leveling feature (but you can add it yourself if you want). The first thing I needed to do before printing was level the bed. I highly recommend this video from Tom to get started with bed leveling. I also use this leveling test gcode from Thingiverse to help tune my bed.

Once the bed was level I kicked off my first print!.. And then canceled it because the test dog that comes preloaded with the printer takes 5 hours to complete. Ain't nobody got time for that!

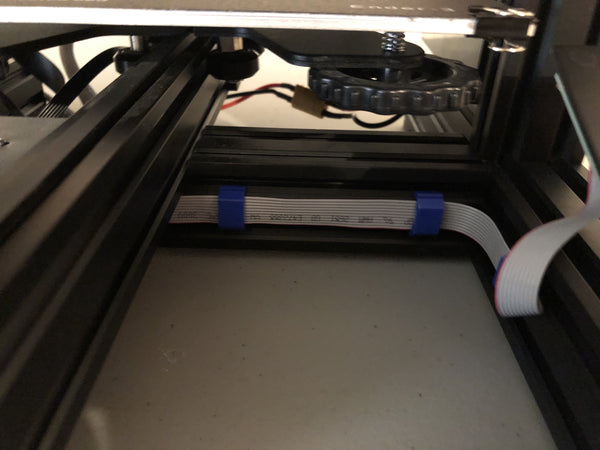

I wanted a quick win, so the very first print from my Ender 3 was to improve the Ender 3. The control panel LCD has a ribbon that's not managed very well. It kind of just flops around. To tidy it up, I printed some cable clips I found on Thingiverse.

They took about 5 mins to complete and came out great! This is what they look like installed on the printer.

The dam was broken

Ever since Christmas morning, I've been completely occupied with solving little paper cuts around my house by designing things to 3D print. We printed command strip hooks to hang hats, coat hangers for the laundry room, a shower drain replacement for our bathtub, crummy wedding bands we're not afraid of messing up, headphone holders (x2), and a few other little things.

This doesn’t include any of the upgrades I printed for my Ender 3 that I felt like were needed after a few prints. While printing, I noticed the filament was going into the extruder at a pretty sharp angle. It became a thing I would always fidget with, so I ended up printing this filament guide from Thingiverse. This one was fun because Wil was standing next to me when the print completed. It went from the bed to on the printer and functional within 30 seconds of it finishing. We turned to each other and giggled like little kids. I just printed this piece of plastic from the internet that fixed a problem for me in an hour!

Another thing that bothered me was how exposed the case fan was below the printing bed. It was so easy for crud to fall right into a spinning fan. To fix that I printed this fan guard from Thingiverse.

Conclusion

The Ender 3 has been an amazing workhorse for me over the past six days. I haven’t been printing constantly but I have been printing multiple things daily (with the print times going up as the parts get more complex). I’ve become somewhat of a pro at leveling the bed, which is nice to not struggle through anymore. I’m not sure the giddy feeling I get as a print finishes and I peel it off the bed will ever fade away. I’m making parts at home.

Would I recommend the Ender 3 to anyone? Hell yea! It’s been exceptional.

Originally published at https://medium.com by Robert DeLuca on December 31, 2018.

.jpg)