What are SLA, DLP, and LCD resin 3d printers? What are their molding principles and differences?

Regarding resin 3D printing, most people may only know the molding method of SLA,(Photo-curing: After being irradiated with light, a special photosensitive printing liquid is cured to become a 3D printed object.) And most people will know that the market prices will come from 1,000 to 10,000 US dollars, even more, which is relatively expensive.

Most of DLP / SLA / LCD 3d printers adopt the photosensitive resin. Photosensitive resin is a mixture of photoinitiator, monomer polymer and prepolymer, this material can be cured under the specific wavelength ultraviolet light focusing. The model printed with photosensitive resin material has a smooth surface, high printing accuracy and high molding quality.

Compared with filament 3D printers, operating resin 3D printers seem to be more challenging.

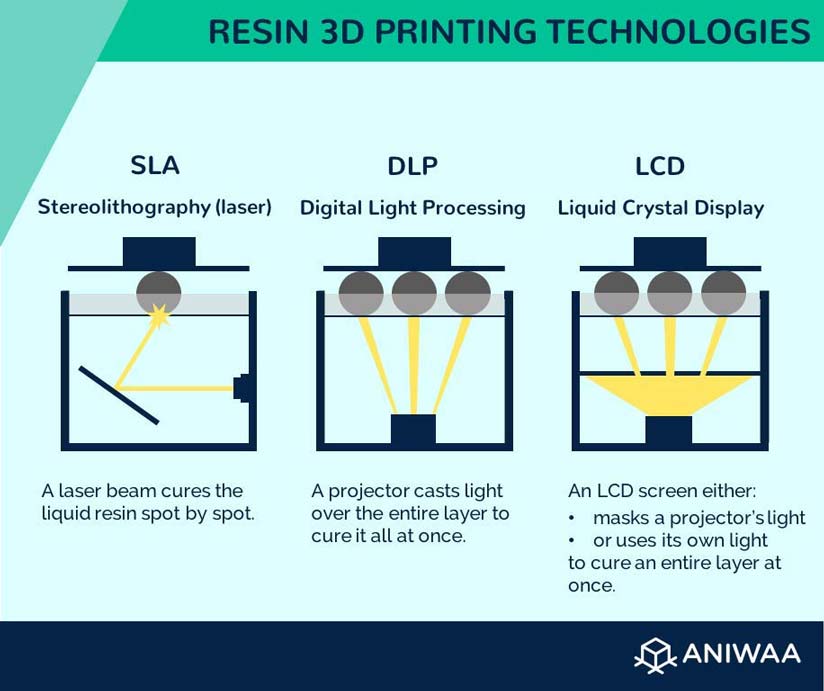

So, what are the differences between SLA, DLP, and LCD?

Regarding "light curing 3D printing", its core is the solution around the light source problem.

(Image Source: www.aniwaa.com )

What is SLA?

SLA is the abbreviation of "Stereo Lithography Apparatus". The laser beam outlines the shape of the first layer of the object on the surface of the liquid photosensitive resin, and then the production platform descends a certain distance, and then the cured layer is immersed in the liquid resin. Finally, after taking the prototype out of the resin, it is finally cured and then polished, plated, painted or colored to obtain the desired product.

What is DLP?

DLP is the abbreviation of "Digital Light Processing", which is digital light processing, that is, the image signal must be digitally processed before the light is projected out. The principle is to pass the cold light source emitted by the UHP bulb through the condenser lens, and use Rod to make the light uniform. The processed light passes through a color wheel to separate the light into RGB three colors (or RGBW) Wait for more colors), and then project the color from the lens on the DMD chip, and finally the reflection is imaged on the projection screen through the projection lens.

What is LCD?

LCD is the abbreviation of Liquid Crystal Display. As the name implies, it is a liquid crystal projector. It is a red, green, and blue color liquid crystal panel, which is transmitted through a lens magnification and a mirror. The light source in the LCD projector is a metal halogen lamp or UHP (cold light source).

So with regard to "light-curing 3D printing", one of its cores is the solution around the light source problem, including software, automation, application and many supporting problems in the industry. The other core issue is the resin, which is another core technology also and very important.

From the principle of light-curing rapid prototyping and the materials it uses, light-curing rapid prototyping mainly has the following characteristics:

Advantages of SLA processing:

- High processing accuracy, can reach 0.1mm;

- It can manufacture complex shapes (such as hollow parts) and particularly fine (such as jewelry, handicrafts, etc.) parts, suitable for fine parts and toys such as mobile phones, radios, walkie-talkies, mice, and high-tech electronic industry housings, home appliance housings or Models, motorcycles, auto parts or models, medical equipment, etc .;

- The speed of manufacturing parts is fast, and can carry out 0.1-0.15mm layered scanning;

- The surface quality is good, can produce very fine details and thin-wall structure, easy post-processing;

- Processing is in place, many details that cannot be processed by CNC can be processed, thus reducing the workload of post-processing;

The advantages of DLP projector:

- From a technical point of view, DLP projectors mainly have three characteristics: high native contrast, miniaturization of the machine, and closed type optical path;

- The DMD chip uses a mechanical working method, the movement controllability of the lens is higher, and the higher native contrast ratio is expected;

- The DLP projector uses the reflective principle, which is more thoughtful for eye protection;

- The DMD chip uses a semiconductor structure, and the lens is not easy to change too much when operating at high temperatures, so the DLP projector uses a closed optical path to reduce the probability of dust entering;

LCD advantages:

- High accuracy: It is easy to achieve a plane accuracy of 100 microns, which is better than the first generation SLA technology and comparable to the current desktop DLP technology.

- Cheap price: Mainly comparing the SLA and DLP of the previous generation technology, this price-performance ratio is extremely outstanding.Simple structure: because there is no laser galvanometer or projection module, the structure is very simple, easy to assemble and maintain

- General resin: Because of the 405nm backlight, all DLP resins or most photocurable resins are theoretically compatible. Only be careful of certain SLA special resins, not necessarily good compatibility, mainly afraid of underexposure.

- Fast printing speed: printing multiple parts at the same time without sacrificing speed, because this is the same as DLP technology, which is a surface forming light source.

Small size, lightweight, and very convenient to carry, it is the mainstream product in the projector market, so it is also gradually popularized in home entertainment and small shopping malls at a lower price.

image from Facebook user group - Francois Sire

image from Facebook user group - Francois Sire

As early as 30 years ago, when the light-curing technology SLA (laser scanning) stereolithography technology began to appear, 3D printing came out. In 2013, makers used ordinary computer LCD monitors to remove the backlight board, and added 405 LED lamp beads as backlight, trying to print uv resin.

So it can be said that light curing is the leader of 3D printing technology. Technical content from:www.3ddyjsw.com

If any points need to add or modify, please let us know.